Sabeela Beevi Ummalyma

Scientist Name: Sabeela Beevi Ummalyma, PhD

Designation/Position: Scientist

Department/Programme Name: Microbial Resources

Phone: 0385-2446122

Academic Qualifications

• 2011-2016, Ph.D, National Institute for Interdisciplinary Science and Technology-CSIR, Trivandrum, Kerala (Awarded from Cochin University of Science and Technology )

• 2005-2007, M.Sc Biotechnology, Thalassery campus, Kannur University, Kannur, Kerala

Experience

• 2018-Till date, Scientist, Institute of Bioresources and Sustainable Development(IBSD), Takyelpat, Imphal-Manipur, India.

• 2016-2017, Post-Doctoral Fellow, IBSD, Imphal-Manipur, India

• September 2015-December 2015, Visiting faculty , Ecole Polytechnique Federal de Lausanne(EPFL), Switzerland

• 2013-2016, Senior Research Fellow, CSIR-NIIST, Trivandrum, Kerala

• 2011-2013, Junior Research Fellow, CSIR-NIIST, Trivandrum, Kerala

• 2009-2011, Production Cum QC Scientist, SCTIMST,BMT Wing, Poojappura Trivandrum, Kerala

Awards & Fellowships

• 2019: Best poster Award in International conference on New Horizons in Biotechnology (NHBT) held during November 20-24, 2019 at CSIR NIIST Trivandrum and the poster entitled “Cultivation of microalgae in pharmaceutical effluent contaminated river water for biofuel and bioremediation.

• 2015: Visiting fellowship from EPFL, Lausanne, Switzerland for visiting faculty for leaning by-products development from lignocellulose biomass and LCA analysis

• 2014: Best poster Award in International conference on Emerging Trends in Biotechnology (ICETB) held at Jawaharlal Nehru University New Delhi and the poster entitled “Evaluation of fresh water micro algal isolates for growth and lipid production in seawater based medium”

• 2009: ICAR-ARS-NET April

• 2009: CSIR-UGC-JRF-NET December

Memberships (Professional Associations / Societies)

• Life Member of Biotech Research Society of India (BRSI)

Specialized Training

• Completed course cum training on Techno-economic and Life- Cycle Assessment as Tools for sustainability analysis International Workshop jointly organized by Biotech Research Society of India and CSIR-National institute for interdisciplinary science and Technology, Trivandrum held at CSIR-NIIST, Trivandrum on July 9-13, 2018

• Attended Three days workshop on “Training in Molecular phylogeny” Organized by UniBiosys Biotech research labs (UBRL) held on 25 -27July2011

• Training in animal handling Programme held from 03.08.2009 to 07.08.2009 in the Division of Animal Science Laboratory, Sree ChitraTirunal Institute for Medical Sciences (SCTIMST) and Technology,Trivandrum.

• Training in Confocal Microscopy from Sree Chitra Tirunal Institute for Medical Sciences and Technology, Trivandrum.

1. Research theme photo

2. Verticals involved

Bioenergy and Biorefinery chemicals

3. Research Area/Research Expertise

• Lignocellulosic biomass to Biofuels

• Biomass pretreatment process

• Enzyme technology

• Microalgal biomass to value addition

• Scale up cultivation of algal biomass in raceway reactor

• Flocculation of algal biomass

• Environmental remediation

• Bioprocess technology for industrial products

4. Research Summary

A. Current Research:

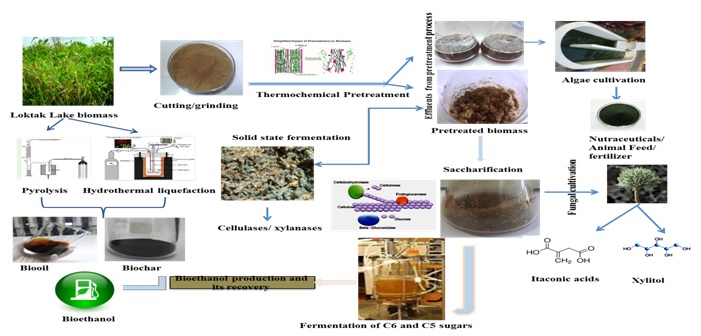

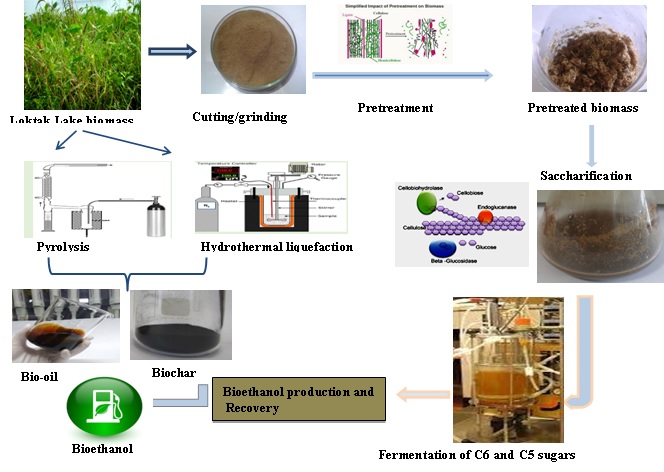

Sustainable utilization of Loktak Lake biomass for biofuels and biorefinery chemicals

Loktak Lake is the largest fresh water Lake in North Eastern India located in Manipur, India and it is unique due to the presence of floating mass of vegetation locally known as phumdis. The largest of these vegetations forms Keibul Lamjao national park, phumdis are home to an endangered species of deer known locally as Sangais which is threatened by loss of habitat. One of the major reasons being the invasive growth exotic grasses such as Para Grass and other aquatic weeds due to pollution and other anthropogenic activities in the lake that killed several indigenous plants that form the feed of Sangais. Efforts are underway to protect this unique habitat. State Government is trying to remove excess phumdies from the Lake. The phumdis removal programme is not effective due to rapid re-growth of phumdis. This again has led to a disposal problem and a solution to the perpetual issue would be value addition the biomass so that it is converted quickly to a product in demand, so that there is local income generation along with disposal of the otherwise waste biomass. We are trying to address the utilization of removed phumdies from the lake as raw material for the conversion of bioethanol and other products through biological routes and bio-oil, biochar conversion and other biorefinery chemicals through thermo catalytic process (pyrolytic and hydrothermal liquefaction).

Fig: Processing of Loktak Lake Biomass to value added products

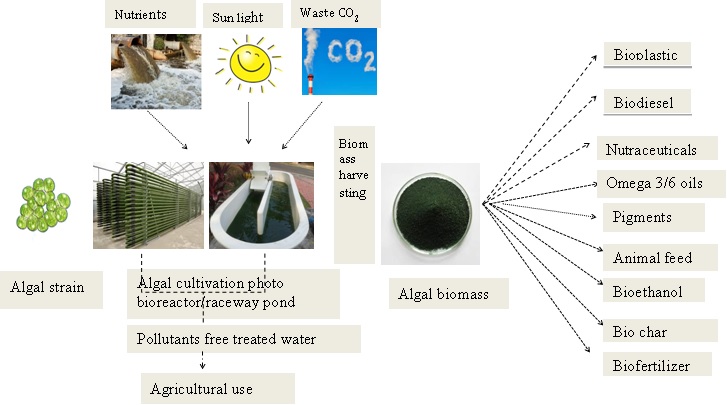

• Microalgal biomass production in wastewater for low cost biomass for value added products and phycoremediation

Microalgal biomass is considered as most potent source of bioenergy and bioproducts due to its ability to accumulate higher oils and carbohydrates content, photosynthetic rate, no competition for agricultural land and easy to handle. There are many challenges associated with microalgal cultivation that hinders its commercialization and scale up processing. Main bottleneck for mass cultivation of microalgal biomass as feedstock for bioenergy required huge quantities of water, high cost of nutrients and harvesting of biomass. The freshwater resources are a costly product in near future and scale up production of algae in freshwater medium is not a practical solution. However it is essential to find an alternative low cost water resource for mass production of algal biomass. Hence the utilization of wastewater is highly encouraged to use as a low cost medium for algal cultivation. We are trying to utilize waste streams as low cost medium for freshwater microalgae cultivation to produce industrial important products. Moreover, algal cultivation in waste water assist in bioremediation of wastewater for removing the pollutants loads for value addition to the waste streams for better environment and mean while produce low cost biomass for industrial applications.

Fig: Microalgal Biomass production in waste waters and waste carbon for industrial applications

B. Previous Notable Research:

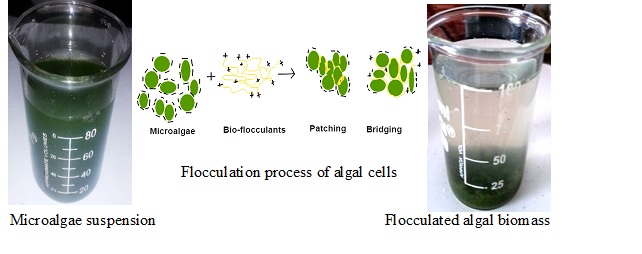

• Harvesting of microalgal biomass: Efficient method for flocculation through pH modulation carried out at CSIR-NIIST, Trivandrum, Kerala.

Microalgae based research has been extensively progressed for the production of value added products and biofuels. Potential application of microalgae for biofuel is recently gained more attention for possibilities of biodiesel and other high value metabolites. However, high cost of production of biomass associated with harvesting technologies is one of the major bottleneck for commercialization of algae based industrial product. Based on the operation economics, harvesting efficiency, technological possibilities, flocculation of algal biomass is a superior method for harvesting microalgae from the growth medium. We are studied the mechanism of harvesting of the microalga Chlorococcum sp. R-AP13 through autoflocculation, chemical flocculants or by change in medium pH. Surface charge of algal cells changed in response to the method adopted

and affected flocculation efficiency of the algal cells. Inorganic flocculants such as aluminum sulfate and FeCl3 supported 87% and 92% efficiency, auto flocculation could recover 75% of biomass in 10 min. Maximum efficiency (94%) was obtained with change in medium pH from 8.5 to 12.0 achieved through addition of 40 mg/l of NaOH. Since high concentrations of FeCl3 and AlSO4 were toxic to the cells, flocculation induced by pH change may be considered the most effective strategy. Residual medium after flocculation could be reused efficiently

for algal cultivation, minimizing the demand for freshwater.

Fig: Flocculation mechanism of Microalgal cells

• Potential of Brachiaria mutica (Para grass) for bioethanol production from Loktak Lake , carried out at IBSD, Imphal

We have evaluated feasibility of using the invasive grass (Para grass) as feedstock for bioethanol. Process involved the pretreatment with dilute acid or alkali and followed by enzymatic saccharification with commercial cellulose, followed by fermentation. Maximum sugar release of 696 mg/g was obtained from 10% biomass loading and 0.5% w/v of alkali whereas in the case of acid pretreatment maximum sugar of 660mg/g was obtained from 20% biomass loading and 2 % w/v acid loading. Results showed that Para grass utilization as a biorefinery feedstock can be a potential strategy to address the sustainable utilization of this invasive grass thereby keeping its population in check in the Loktak Lake. B.mutica available from the Loktak Lake, can be used as raw material for bioethanol and other value added chemical productions without extra input on the food crop land. NaOH based pretreatment is the low cost process compared to acid. IBSD first reported on pretreatment and hydrolysis of B.mutica of Loktak Lake of North Eastern India for ethanol production.

A. Research Articles

1. Singh A, Ummalyma SB (2020) Bioremediation and Biomass production of microalgae cultivated in River water contaminated with pharmaceutical effluent. Bioresource Technology.307:123233. Impact factor 6.6, PubMed ID:32240927

2. Ummalyma SB, Sukumaran RK, Pandey A (2020) Evaluation of Freshwater Microalgal isolates for growth and oil production in sea water medium. Journal of waste Biomass Valorisation.11: 223-230. Impact factor 2.4, Article Link: https://doi.org/10.1007/s12649-018-0393-8

3. Sahoo D, Awasthi A, Singh G, Dhyani V, Kumar J, Reddy YS, Adarsh VP, Puthiyamadam A, Kumar K, Sukumaran RK, Ummalyma SB, Bhaskar T(2019) Value addition of water hyacinth and para grass through pyrolysis and hydrothermal liquefaction. Carbon Resource Conversion.2: 233-241, Article Link: https://doi.org/10.1016/j.crcon.2019.08.001

4. Puthiyamadam P, Adarsh VP, Mallapureddy KK, Mathew A, Kumar J, Yenumala SR, Bhaskar T, Ummalyma SB, Sahoo D, Sukumaran RK (2019) Evaluation of wet processing strategy for mixed phumdi biomass conversion to bioethanol. Bioresource Technology. 289:121633. Impact factor 6.6, PubMed ID: 31248726

5. Awasthi A, Singh G, DhyaniV, Kumar J, Reddy YS, AdarshV.P, Puthiyamadam, A, Kumar K, Sukumaran RK, Ummalyma SB, Sahoo D, Bhaskar,T (2019) Co- pyrolysis of phumdi and para grass biomass from Loktak Lake. Bioresource Technology. 285: 121308. Impact factor 6.6, PubMed ID: 30959390.

6. Ummalyma SB, Devi RS, Kumar S (2019) Dioscorea puber Blume. (Dioscoreaceae): a new addition to the flora of Manipur. Adv Plants Agric Res. 9(1):58?59. Article Link: https://doi.org/10.15406/apar.2019.09.00411.

7. Ummalyma SB, Devi RS, Patra JK, Kumar S (2018) Ethnobotanical Values of Dioscorea Species Available in Eastern Ghats, India. Basic Appl Pharm Pharmacol. 1(1):103. Article Link: https://doi.org/10.31021/bapp.20171103.

8. Sahoo D, Ummalyma SB., Okram AK, Pandey A, Sukumaran RK, Meena S (2018) Effect of dilute acid pretreatment of wild rice grass (Zizania latifolia) from Loktak Lake for enzymatic hydrolysis. Bioresource Technology. 253: 252–255. Impact factor 6.6, PubMed ID: 29353753.

9. Ummalyma SB, Devi RS, Kumar S (2018) Dioscorea hispida Dennst. (Dioscoreaceae) : A new addition to thestate flora of Manipur, India. Pleione. 12(1): 147 - 149. Article Link: https://doi.org/10.26679/Pleione.12.1.2018.147-149.

10. Sahoo D, Ummalyma SB, Okram AK, Sukumaran RK, George E, Pandey A (2017) Potential of Brachiaria mutica (Para grass) for bioethanol production from Loktak Lake. Bioresour Technol. 242:133-138 Impact factor 6.6, PubMed ID: 28341381

11. Sindhu R, Binod P, Mathew AK, Ebraham A, Gnansounou E, Ummalyma SB, Thomas L, Pandey A (2017) Development of a novel ultrasound-assisted alkali pretreatment strategy for the production of bioethanol and xylanases from chili post harvest residue. Bioresour Technol. 242:146-151. Impact factor 6.6, PubMed ID: 28286012

12. Ummalyma SB, Sukumaran RK, Mathew A, Pandey A (2016) Harvesting of microalgal biomass: Efficient method for flocculation through pH modulation. Bioresour. Technol. 223,216-221. PubMed ID: 27036330.

13. Ummalyma SB Sukumaran R K (2015) Cultivation of the fresh water microalga Chlorococcum sp. RAP13 in sea water for producing oil suitable for biodiesel, J. Appl Phycol27,141–147. Impact factor 2.8. Article link: https://doi.org/10.1007/s10811-014-0340-4

14. Ummalyma SB, Sukumaran RK (2014) Cultivation of microalgae in dairy effluent for oil production and removal of organic pollution load. Bioresurce Technology.165: 295-301. Impact factor 6.6, PubMed ID: 24703181

B. Review Articles

1. Sindhu R, Binod P , Ummalyma SB, Amith, MathewA.K, Madhavan.A, Rebello S, Pandey A (2018) Applications of Microbial Enzymes in Food Industry. Journal of food Technology Biotechnology. 16-30. Impact factor 1.6, PubMed ID: 29795993.

2. Sindhu R, Binod P, Mathew A K, Ebraham A, Madhavan A, UmmalymaS B, Pandey A (2017) Molecular improvements in microbial ?-amylases for enhanced stability and catalytic efficiency. BioresourTechnol. 245(Pt B): 1740-1748. Impact factor 6.6, PubMed ID: 28478894

3. Binod P, Sindhu R, Madhavan A, Ebraham A, Mathew AK, Ummalyma SB, Sukumaran RK, Pandey A (2017). Recent developments in L-glutaminase production and applications - an overview. Bioresource Technology. 245(Pt B): 1766-1774. PubMed ID: 28549811

4. Ummalyma SB, Gnansounou E, Sukumaran RK, Sindhu R, Pandey A, Sahoo D( 2017). Bioflocculation: An alternative strategy for harvesting of microalgae – an Overview. Bioresour.Technol. 242:227-235. PubMed ID: 28314665.

C. Book Chapters

1. Ummalyma SB, Sahoo D, Pandey A (2020) Microalgal biorefineries for industrial products. Book of Microalgae Cultivation for Biofuels Production. Elsevier, 187-196.

2. Ummalyma SB, Devi RS (2019) Lasia spinosa: Wild Nutraceutical for Formulation of Future Drugs. Book of Ethnopharmacology and Biodiversity of Medicinal Plants. CRC Press Tailor and Francis group.265-285.

3. Ummalyma SB, Sindhu R, Binod P, Pandey A, Gnansonuou E (2019) Polyunsaturated Fatty Acids (PUFAs). Book of High Value Fermentation Products. Scrivener publishing.2: 109-126.

4. Ummalyma SB, Sahoo D, Pandey A(2019) Bioremediation and Biofuel Production from Chlorella sp.: A Comprehensive Review. Book of Microalgae Biotechnology for Development of Biofuel and Wastewater Treatment. Springer. 635-655.

5. Ummalyma SB, Devi RS, Sindhu R, Binod P, Nair RB, Pandey A, Gnansounou E(2019) Biological pretreatment of lignocellulosic biomass—current trends and future perspectives. Book of 2nd and 3rd Generation of Feedstocks. Elsevier, 197-212.

6. Ummalyma SB, Sahoo D, Pandey A, prajeesh KV (2019) Microalgae–Microbial Fuel Cell. Book of Microbial fuel cells materials and applications. Material Research Foundation USA, 46: 1-20.

7. Ummalyma SB, Sindhu R, Binod P, Pandey A, Gnansounou E(2019) Sorbitol demineralization by ion exchange. Book of Applications of Ion Exchange Materials in Biomedical Industries. Springer, 155-161.

8. Ummalyma SB, Pandey A, Sukumaran RK, Sahoo D (2018) Bioremediation by microalgae: Current and emerging trends for effluents treatments for value addition of waste streams. Book of Biosynthetic Technology and Environmental Challenges Springer, 355-375

9. Sukumaran RK, Sankar V, Madhavan A, Sankar M, Satheesh V, Omar Idris AS, Ummalyma SB (2016) Enzyme Technologies: Current and Emerging Technologies for Development of Novel Enzyme Catalysts. Book of Enzymes in Food and Beverage Processing. CRC Press, Ohio, USA 29-66.

Group Photo:

Group Members (Details):

|

1. |

Name: Anamika Designation: Project Fellow (IBSD Core) Email: anamikaankuranjan@gmail.com Problem Addressing: Biomass pretreatment approach of lignocellulose for biorefineries. Expected Outcome: understands how the different pretreatment process affecting the biomass structure and its hydrolytic process. |

|

|

Previous Members (Alumni) |

||

|

1. |

Name: Baibhav Karki Designation: Project Fellow ( IBSD Core) Email: baibhavkarki@gmail.com Worked on – Biomass processing for biofuels and biorefineries Currently working at: Sikkim Manipal University, Sikkim |

|

A. Core/Internal

a. Present:N/A

|

Sl. No. |

Duration (From-To) |

Title of Project/ Grant |

PI/Co-PI |

Funding Agency |

Amount |

|

|

NA |

|

|

|

|

b. Past:

|

Sl. No. |

Duration (From-To) |

Title of Project/ Grant |

PI/Co-PI |

Funding Agency |

Amount |

|

1 |

2017-2019 |

Utilization of Loktak Lake biomass for biofuels and biorefinery chemicals |

Co-PI |

IBSD |

N/A |